In lime concrete, the sand serves as the fine aggregate, while gravel serves as the coarse aggregate in the proper ratios.

The lime concrete mix ratio might go up to a 1:2:3 ratio for lime, sand, and coarse aggregate, due to the type of building projects.

In this article you’ll learn:

- Purpose of the lime concrete.

- Types of lime concrete.

- Merits and Demerits of the lime concrete.

- Lots more.

So, if you’re ready to go with it, this article is for you.

Let’s get in right now.

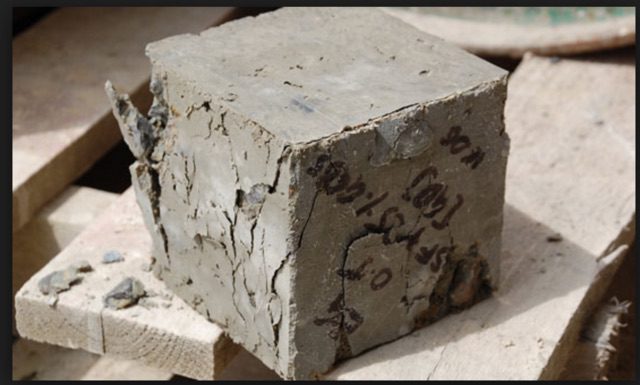

What is Lime Concrete?

Lime concrete had a wide range of applications in the construction industry before the use of cement as a binding material became popular.

By placing it on top of the vapor-permeable insulation base can be obtained, it is also utilized as a capillary break.

They are widely used prior to Portland cement’s replacement of the lime matrix and contained a combination of gravel, sand, and lime.

Lime Concrete Preparation:

Concrete Mortar:

A mortar made of plain lime, lime pozzolana, or lime cement in the correct ratios of the various ingredients must be used.

A dry form of lime must be used, the putty or hydrated lime must be prepared in accordance with IS1635: 1975.

The mortar must be made in accordance with the guidelines outlined in IS 2250: 1981.

Coarse Aggregate:

Before use, coarse aggregate must be thoroughly cleaned and drained if it contains an excessive amount of dirt.

Burnt clay, cinder, and another porous coarse aggregate must be thoroughly moistened before use.

Mixing:

Both a small hand mixer and a pair of hands can be used to mix lime concrete. The use of a mechanical mixer would be preferable for larger quantities.

Two types mixing:

1. Machine mixing:

Pouring the measured amount of wet ground mortar and coarse aggregate into the mixer’s drum as it rotates is how mixing is to be done.

The number of materials loaded into the drum cannot be greater than the mixer’s rated capacity.

A batch of concrete must be wet and mixed in the drum for at least two minutes until it has a uniform color, evenly distributed materials, and consistency.

Water must be added gradually until the required amount is reached.

The lime concrete’s consistency must prevent the mortar from tending to detach from the coarse aggregate.

After being removed from the mixer, the concrete needs to be removed if there is segregation.

The entire batch of concrete must be terminated before the ingredients for the new batch are started pouring into the container.

Before ceasing work, the mixer must be cleaned by turning the water-filled drum repeatedly.

2. Hand mixing:

When specifically allowed, hand mixing must be performed on a dry, watertight masonry platform large enough to accommodate the necessary mixing space.

The wet lime mortar that is specified must be applied on top of the aggregate.

Until a uniform mixture of the desired consistency is obtained, turning must be done repeatedly while the necessary amount of water is added.

The lime concrete’s consistency must prevent the mortar from tending to detach from the coarse aggregate.

Laying of Lime Concrete:

Placing and compaction:

When the lime concrete is still fresh, it must be laid out in layers.

Before laying the next layer of this concrete, the previous layer must be thoroughly rammed and consolidated.

Each layer cannot be thicker than 15 cm when combined. If not otherwise specified, joints should be spaced out in different layers when necessary.

Heavy iron rammers weighing between 4.5 and 5.5 kg must be used, and their surface area cannot exceed 300 sq. cm.

Ramming must continue until the this concrete has been laid out completely and is covered in a skin of mortar.

Even before work is stopped, the concrete that was laid on a specific day must be thoroughly consolidated.

Freshly laid concrete must have appropriate coverings to protect it from rain.

Lime Concrete Curing:

The concrete must be cured by keeping it damp with wet gunny bags, sand, or any other method for a minimum of 7 days after it has started to harden, or roughly 24 hours after it has been placed and compacted.

Advantages of Lime Concrete:

- Lime concrete has the desired plasticity and offers good workability.

- It has a certain level of waterproofing property, which prevents subsoil dampness.

- It withstands the effects of weathering.

- Bases made of this concrete can support enough weight.

- At the beginning of the setting process, it achieves a significantly lower compressive strength.

- It is more environmentally friendly than typical Portland cement because it uses less energy to produce the lime and produces less carbon dioxide during the carbonation process.

Disadvantages of Lime Concrete:

- More time is required for setting.

- In general, hydraulic lime develops strength more slowly than cement concrete for the same strength.

- Although the ancient world had plenty of time, today’s time is money, and lime cement takes a very long time to cure.

- In water, lime cement does not harden but rather remains soft.

Application of Lime Concrete:

- This concrete can be used to build the foundation for load-bearing walls.

- For flooring, lightweight clay or pumice mixed with this concrete serves as an insulator.

- It can be used to build temporary structures or unimportant structures that are built to make building permanent structures like tunnels, bridges, retaining walls, dams, and other similar structures easier.

Also read: Lime Plaster | Types of Mortar | Lime Mortar

Conclusion:

Lime Concrete has more desirable features Especially in comparison to mortar made only of concrete.

These characteristics combined with its resistance to severe weathering, making it a superior option.

Any cracks that appear in the mortar as a result of structural movement can be repaired with lime in concrete.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment