Polymer modified concrete (PMC) is also known as polymer-Portland cement concrete (PPCC) and latex-modified concrete (LMC).

It is explained as a mixture of Portland cement, aggregate, and organic polymers that have been distributed or redispersed in water.

In this article you’ll learn:

So, if you’re ready to go with polymer-modified concrete, this article is for you.

Let’s dive right in.

What is Polymer Modified Concrete?

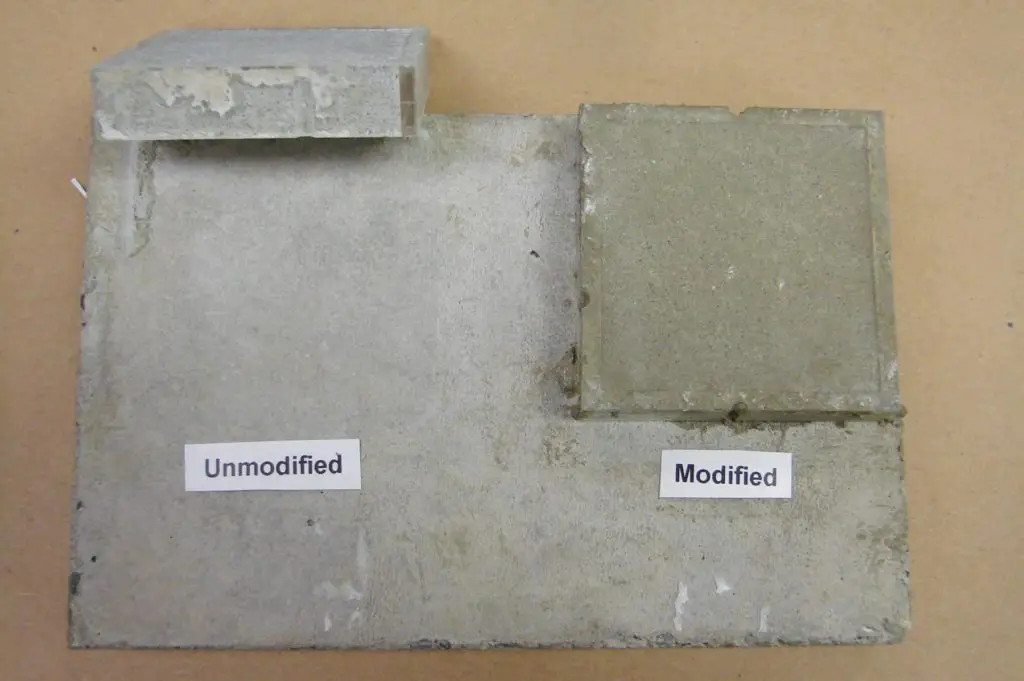

Concrete that has been combined with polymeric material is known as polymer-modified cement concrete.

The hydration process shouldn’t be hampered in any way by the polymers that are added.

The only ways to add many polymers are emulsion, dispersion, or latex because they are frequently insoluble in water.

The formed composite is then casted in the desired shape using the standard building method.

Later, the curing is done in a manner similar to concrete is normally done.

The hydrated cement and the polymer film formed during the curing of the polymeric material combine to form an interpenetrating matrix that binds the aggregate together.

Polymeric materials such as structure and prepolymers can be used to modify cement concretes, the polymers required for this concrete are in small quantities.

This ranges from 1% to 4% by weight of the composite, the least expensive possibility is polymer-modified concrete.

PMC processing has been discovered to be very simple and mechanical properties are not satisfactory.

Concrete with polymer impregnation performs better than concrete with polymer modification in terms of mechanical properties.

Purpose of Polymers Modified Concrete:

- Old, damaged concrete can be repaired and renovated using polymer-modified concrete.

- Floor construction finds extensive use in factories that produce frozen foods.

- This is brought by PMCs’ greater resistance to freezing and thawing.

- Factory floors were more likely to experience chemical and oil splitting than other parts of the building.

- For the purpose of preparing the surfaces of steel ships and bridges the concrete building that is more frequently subjected to heavy de-icing salt loads.

Types of Polymers Modified Concrete (PMC):

1. Latex-Modified Cement Concrete:

The lattices are suspensions of very small polymer particles, which resemble white milk that are kept suspended in water by the use of emulsifiers and stabilizing agents.

In terms of mass, it has a polymer solid content of about 50%.

For modifying cement concrete, lattices have been constructed using both elastomeric and glassy polymers.

It gives the reinforcement high, higher strength, and low corrosion rates.

The latex additives can be kept in an environment that provides enough protection from freezing and temperature exposure for the mixture.

It must be properly covered with an appropriate insulating blanket if the drum holding the mixture is exposed to sunlight.

Less than 85°F must be maintained as the interior temperature.

Among the most widely used elastomeric latex are rubber latex, acrylonitrile-butadiene, neoprene, and natural rubber latex.

The glass polymer-modified concrete fail in a brittle manner that have a higher elastic modulus and strength.

Some common examples include polyvinylidene chloride, acrylic polymers, polyvinyl acetate, and styrene-butadiene copolymer latex.

Due to the lingering chlorine that causes the reinforcement to corrode, polyvinylidene copolymer is used in applications involving unreinforced concrete.

The ideal curing temperature is formed by moist curing composite for one to seven days.

After that, dry curing occurs.

The latex-modified concrete would have reached its maximum strength after 28 days of curing.

2. Prepolymers-Modified Cement Concrete:

This concrete includes polyester-styrene, epoxy, and furan.

This kind of PMC strengthens concrete in comparison to conventional concrete by a factor of 50–100%.

It is adhesion ability is strong, and it has better durability qualities.

In comparison to conventional concrete, the tensile strength and rupture modulus are more than twice as high.

Concrete made with pre-polymer-modified cement experiences less microcracking formation.

This concrete has a lower water-cement ratio and pores that have been filled.

This helps to increase the concrete’s durability.

Even, the increased strength of this concrete is not calculated taking into account the cost of the polymer.

Properties of Polymer Modified Concrete:

- The traits of concrete modified with polymers are as follows:

- The concrete mix is made more workable by the addition of polymers, this may mean that less water needs to be added to the concrete mix.

- The polymer in concrete increases the concrete’s crushing strength due to the polymer’s ability to lower the water-to-cement ratio, which raises crushing strength.

- The aggregate and matrix now have a stronger bond.

- The polymer modification improves the concrete’s flexural strength.

- In comparison to plain concrete, polymer-modified concrete contains at least 3% more entrained air, the concrete’s elastic modulus will decrease due to the additional entrained air (PMC).

- Concrete takes a long time to set after the addition of polymer.

- The use of the polymer increases the concrete’s resistance to abrasion.

- Polymer modification increases the concrete structure’s resistance to freezing and thawing.

- Chlorine ions and other harmful substances cannot penetrate very far.

- Superior shear bond strength is gained by the PMC.

- It has a higher level of ductility.

- They become stronger than traditional concrete in the tensile and flexural areas.

Advantages of Polymer Modified Concrete:

- Increased strength and durability:

The strength of the concrete depends on quantity of water is added to the mixture.

Strength increases as the water-to-cement ratio are reduced, and this concrete uses less water as a result.

- Better workability:

Concrete is stronger when less water is used, but it is more difficult to pour.

- Lower water permeability:

The formation of a latex film occurs as water is removed by hydration and latex particles coalesce, it improves the bond strength and mechanical properties of the concrete.

- Increased freeze-thaw stability:

The polymer-modified concrete’s decreased water permeability also protects against damage from frequent freezing and thawing.

- Better chemical resistance:

This concrete is typically more resistant to common chemical assaults.

Disadvantages of Polymer-Modified Concrete:

- Polymer-modified concrete is very expensive.

- When mixing, this concrete requires high levels of skill and precision.

- Two-component materials can be improperly proportioned, so the right mix design is necessary.

- It is essential to wear masks and hand gloves for skin protection because the chemicals or resins used in this concrete can be hazardous.

Also read: Polymer Concrete | Rice Husk Ash Concrete | Bendable Concrete | Vacuum concrete

Conclusion:

Polymer-modified concrete is used in a variety of applications including better repair techniques, structural uses, architectural components, etc.

Therefore, selecting the right choice will affect the success or failure of the structure and the durability of the repaired structure.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment