A composite material is a combination of two materials with different physical and chemical properties. When combined they produce a material that is specific to a certain work, for instance, to become stronger, lighter, or resistant to electricity and also improve strength and stiffness.

The components maintain their identity within the composite, i.e. they do not dissolve or completely merge into one another, though they act in concert.

Here we will learn about composites material, types of composites material & much more.

Introduction to composites material:

Composites material are probably the most extensively used materials due to their adaptability to varied situations.

It is easy to mixed with different materials and the efficiency of desirable properties to serve particular functions.

The composite materials has excessive strength and hardness with decrease density than bulk materials.

Properties of composite materials:

- The tensile strength of composite materials is 4-6 times higher than conventional materials such as steel, aluminum, etc.

- They have better torsion and stiffness properties.

- It has a high fatigue endurance limit (ultimate tensile strength of up to 60%).

- They are 30–45% lighter than aluminum structures designed for the same functional requirements.

- Also has low embedded energy.

- Composites make less noise during operation and provide less vibration.

- Composite materials are additional versatile.

Types of composite materials:

1.Polymer Matrix Composites (PMCs):

It consists of polymer resin within the type of a matrix, the variety and the greatest amount is being used.

Glass fibre-reinforced polymer composites (GFRP) are the largest amount of produced carbon fibre-reinforced polymer composites (CFRP).

2.High-Performance Composites.

They are Aramid Fiber Reinforced Polymer Composites (AFRPs).

It has high strength, high modulus and high impact resistance composites.

3.Metal Matrix Composites (MMCs):

It is also extra ductile compared to matrix reinforcement.

Reinforcement can improve strength, abrasion resistance, creep resistance, thermal conductivity and dimensional stability of composite composites.

Metal matrix composites are additional resistance to extreme working temperatures, non-flammability, and corrosion of organic fluids.

4.Ceramics Metal Composites (CMCs):

For use in high temperature and severe stress applications, e.g. automobile and aircraft gas turbine engines.

It has high strength, very high service temperature & Low weight.

Classification of composite materials:

Microspheres:

They are considered to be some of the most useful filters.

This particular gravity, fixed particle amplitude, power and managed density is the most extreme property for switching products without compromising profitability or physical properties.

Stable micro-spheres have a relatively low density hence affecting the commercial value and weight of the finished product.

Studies shows that their specific strength is covered in the finished mould, in which they form a component.

Hollow microspheres are basically silicate-based constructed at managed specific gravity.

They are larger than the stationary glass spheres used in polymers and are commercially supplied in a wide range of particle sizes.

Filled composites:

The filler may be a core component or addition in a composite.

The particles of the filler may be irregular structures or may contain precise geometric shapes such as polyhedrons, small fibres, or spheres.

Filled composer fillers may be a core component or an addition to a composite.

The particles of the filler may be irregular structures or may contain precise geometric shapes such as polyhedrons, small fibres, or spheres.

Flakes Structures:

Flakes are often used in place of fibre because it can be stored in dense packs.

Metal flakes that has close contact with each other in polymer matrixs can conduct the electrical energy or heat while opposing both mica flakes and glass.

Flexes will not be expensive to produce and will generally have a lower price than fibre.

Particulate Reinforced Composites:

Microstructures of metal and ceramic composites, which show particles of one phase scattered in another are called particle reinforced composites.

The square triangular and spherical shapes of reinforcement are recognized, however the dimensions of all their sides are considered roughly equal.

The size and volume concentration make it different from the dispersion hardened material.

Laminar Composite:

Laminar composites are found as the number of materials in many combinations, they can be described as materials in which layers of material are bound together.

These may consist of several layers of two or more metal materials alternately or in a prescribed order, as many numbers are necessary for a specific purpose.

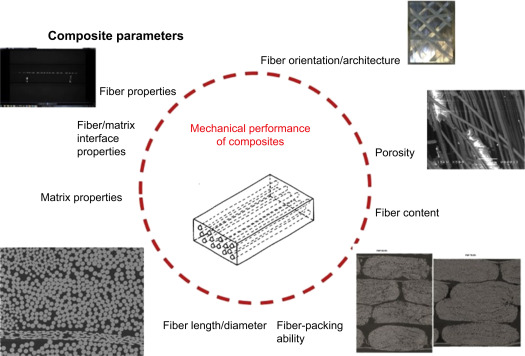

Fibre Reinforced Component:

Fibres are essential for reinforcement, as they meet specified conditions and transfer strength to affect the matrix element and improve their properties as desired.

Application of composite materials:

FRP In trains:

Composite materials are progressively used in the railway industry, saving up to 50% for structural and 75% for non-structural applications at high speeds, low power consumption, low inertia & track wear and carrying more loads.

Now, increasingly components are made from GFRP, which additionally resists corrosion and has excellent performance.

Road Bridge:

The fibre-line bridge was designed by the Danish engineering firm, Ramboll utilizing prevailing profiles.

The 40-meter (131-ft) long, 3-meter (9.8-ft) wide crossings of pedestrians, bicycles and motorbikes that run on an already dangerous set of rail tracks.

FRP doors and window frames:

Doors made of FRP skins are sandwiched with core materials such as flexible polyurethane foam, expanded polystyrene, paper honeycomb.

Jute/coir felt and many others might have potential use in residential buildings, offices, schools, hospitals, laboratories and many others.

Materials for Highways:

Use of carbon fibre reinforced polymer (CFRP) straight and draped tendons for pre-stressing 31.2-meter span girders.

Use of CFRP stirrups for shear reinforcement’s two main girders.

Use a glass fibre reinforced polymer (GFRP) reinforcement for the bridge curb.

Smart Concrete:

Unlike conventional concrete, smart concrete has the next capability and increased power.

Smart concrete might be prepared by adding carbon fiber to be used in electromagnetic shielding for increased electrical conductivity of concrete.

Under the loading and unloading course of the smart concrete will loosen and regain its conductivity thus acting as a structural material in addition to a sensor.

Smart concrete performs a vital role within the development of highway pavements as a traffic-sensitive recorder and melts snow during the winter season within the snow season and low voltage present through it.

Rehabilitation and Retrofit:

In these cases, the material is often bonded externally to the construction within the form of tow (fibre bundles), garments, plates, stirrups and jackets.

Advantages offered by composites in these kinds include their capability to bond nicely with many substrate materials and cling to complicated shapes.

Using 64 fibre optic sensors and 16 conventional power resistance pressure gauges to observe the bridge from the bridge to the central monitoring station remote.

Advantages of composite materials:

- They are light in weight and have low density.

- It has high creep resistance.

- Strength-to-weight and stiffness-to-weight are greater than in steel or aluminum.

- Fatigue properties are higher than normal engineering metals.

- Composites cannot corrode like steel.

- Ease of fabrication of large advanced structural shapes or modular-modular constructions.

- The ability to include sensors into the fabric to monitor its performance-smart composites.

- It has excessive resistance to impression damage.

- Also, enhance corrosion resistance.

Disadvantages of composite materials:

- It has an excessive price for raw materials and manufacture.

- Composites are extra brittle than wrought metals, thus they get additionally damaged.

- The transverse properties are also weak.

- The matrix is weak, so there is very little toughness.

- Reuse and disposal of composite material will be difficult.

- It is difficult to attach.

- Difficulty with analysis.

- Costs may fluctuate.

Also read: GFRG Panels, Papercrete & Geosynthetics

Conclusion:

Composite materials have good mechanical, electrical, chemical properties; due to which we will use composite materials in many different industries.

Various parts of automobiles and aerospace are manufactured with composite materials as a result of their worthy properties.

Thank you very much for your lesson.