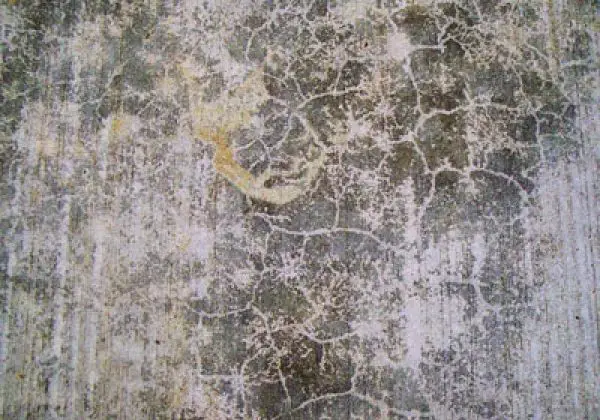

Concrete laitance is a thin layer of cement with small aggregate particles that is weak and transitory.

These components are transported upward due to moisture migration (bleeding) through concrete affected by the addition of too much mixing water.

In this article you’ll learn:

So, if you’re ready to go with it, this article is for you.

Let’s dive right in.

What is Concrete Laitance?

A deposit of microscopic particles on the surface of fresh concrete is caused by water moving upward (as when excessive mixing water is used).

Overworking or over manipulation of the surface of the concrete, improper finishing, or job traffic raise the quantity of cement and fine particles (concrete laitance layer).

In addition to inadequate surface curing, which contributes to the production of laitance.

Laitance can range in thickness from fine dust to several millimeters depending on the underlying reasons.

Causes of Concrete Laitance:

- Excessive mixing of water.

- Overworking or excessively altering the concrete surface.

- Poor curing regime due to improper finishing.

Removal Methods for Concrete Laitance:

Laitance removal is crucial for ensuring that materials placed on the floor such as painting and coating, adhere effectively to it.

There are numerous methods for removing laitance, and the method used should be determined by the working environment and function of the floor.

1. Shot Blasting Technique:

Shot blasting is said to be a quick and efficient method of removing laitance.

It entails hurling abrasive particles toward the concrete surface at high speeds.

Besides, shot blasting technology is expected to clear a minimum area of 1000 square meters every single day.

Shot blasting is a dry technique that is beneficial since floor laying may proceed in other areas of the space while shot blasting is taking place.

Finally, it is thought to be significantly faster, quieter, and cleaner than other processes like mechanical planning, scabbling, and sanding.

2. Mechanical Planning Technique:

Mechanical planning also known as concrete planning is used to remove thicker layers of concrete laitance.

The machine has rows of revolving tungsten-tipped cutters that enable exceptional laitance removal.

3. Scabbling Technique:

It is a tough procedure that makes use of compressed air tools.

The vibrating compressed air tools make contact with the concrete.

Scabbling is a time-consuming, dusty, loud, and filthy operation.

4. Grinding Technique:

For smaller regions and edges, this strategy is employed.

Handheld grinding devices with accuracy, control, and safety features for removing concrete laitance.

5. Acid Etching Technique:

This method is utilized for very thin concrete laitance and non-porous or low-porosity surfaces.

The acid assaults and dissolves the top surface, which is a very efficient procedure.

This should only use when all other alternatives have been exhausted.

6. Abrading Technique:

There are several methods for abrading concrete and removing laitance, such as blasting or using abrasive materials.

However, their uses are limited and are not commonly employed in broader regions.

Difference between Laitance and efflorescence in concrete:

Laitance and efflorescence are not the same things, yet they are white and powdery compounds.

Laitance in Concrete:

The Laitance occurs when there is too much water in the concrete mix.

Controlling the amount of water in the concrete mix can contribution in avoiding it.

Removal procedures include shot blasting, mechanical planning, scabbling, grinding, acid etching, and abrading.

Efflorescence in concrete:

It is the build-up of soluble salts in concrete-on-concrete surfaces.

They can be avoided or reduced by using materials free of hazardous salts and avoiding water from infiltrating the concrete.

The removal procedure employs pressurized water, sand ballasting, and chemical acid washing.

How to eliminate Laitance in Concrete Structures?

Laitance and efflorescence have a similar treatment.

Laitance is the thin milky coating that develops on top of fresh concrete and is mostly calcareous.

Efflorescence occurs after the concrete has been there for a while that can form on an off-form or other surface.

Preventive measures are the same as any other measure of effective mix design as follows:

- Use excellent, sound, and clean aggregates.

- Optimize the particle size distribution in the mix.

- Choose a suitable Portland cement.

- To minimize Portland cement content, use SCMs (supplementary cementitious materials) / mineral admixtures such as fly ash, slag (GGBFS), silica fume, rice husk ash, and so on as a Portland cement replacement.

- Limit your permissible slump.

- The Concrete pump operators will always want a greater slump than is required.

- Reduce the amount of water content.

- Place the concrete correctly.

- Do not drop it from an extreme height.

- Compact the concrete to the desired degree.

- Bring no more bleed water to the surface than is absolutely necessary, and do not separate it.

- Finish it at the appropriate moment until most of the bleed water has evaporated and/or been reabsorbed.

- Cure the concrete since it will not cure itself (by covering it with plastic, spraying it with water, etc).

- Don’t add milk to your coffee, it is unlikely to disintegrate.

Also read: Concrete Screed | Concrete Spalling | Concrete Forms

Conclusion:

A concrete laitance can contribute to rusting.

When metallic constructions are bonded to or placed on a cement basis with a laitance, moisture can be absorbed between both the concrete and the metal surface generating fissure corrosion or pitting.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment