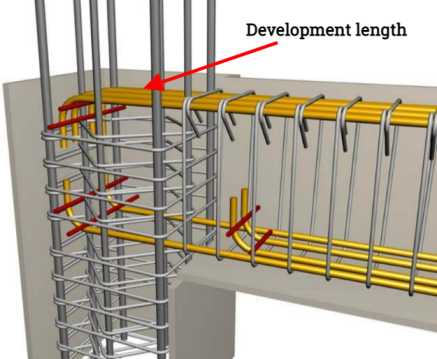

A Development length is the minimum length of the bar needed on either side of the point of greatest steel stress in transferring the bar’s force to the surrounding concrete through a solid bond and preventing the bar from pulling out under tension.

It is also Additionally known as anchorage length.

In this article you’ll learn:

- Purpose of the development length.

- The formula of development length.

- Merits and Demerits of the development length.

- Lots more.

So, if you’re ready to go with it, this article is for you.

Let’s dive right in.

What is Development Length?

A development length is a piece of reinforcement (bar) that needs to be implanted into or forecasted into a column in order to achieve the necessary bond strength between both the concrete and steel.

According to IS 456:2000, each side of the tension or compression member at any section must be developed by providing an appropriate length.

In slabs, continuous beams, and column-beam joints the development length is provided.

Purpose of Development Length:

- The availability of appropriate development is a crucial aspect of safe construction practices.

- The proper length for reinforcement bars must be provided and it will be susceptible to failure due to slippage of joints, bonds, anchors, and laps.

Development Length Formula:

The equation below is used to determine development length;

Ld= φ σ s/4 τ bd.

Were,

Ld is the steel bar’s embedded length.

In steel, σ s is the allowable stress.

Bond-related stress is τ bd.

The diameter of the bar is Φ

For every given bar diameter, this equation is used to determine the required length in mm, both the working stress procedure and the limit state method are determined using the same formula.

The previously stated formula is used to calculate the required development length in mm for any specified bar diameter.

The only difference in estimation between the two methods is caused by the working stress and limited state design bond values, which are as follows:

Table No 1: Design Bond Stress in Limit State Method:

| Design Bond Stress in Limit State Method | ||||||

| M20 | M25 | M30 | M35 | M40 and above | – | |

| Concrete Grade | 1.2 | 1.4 | 1.5 | 1.7 | 1.9 | For Plain Bars in Tension |

| Design Bond Stress (?bd, N/mm2) | 1.92 | 2.24 | 2.4 | 2.72 | 3.04 | For deformed bars in tension |

Table No 2: Design Bond Stress in Working Stress Method:

| Design Bond Stress in Working Stress Method | ||||||||

| – | M20 | M25 | M30 | M35 | M40 | M45 | M50 | – |

| Concrete Grade | 0.8 | 0.9 | 1 | 1.1 | 1.2 | 1.3 | 1.4 | For Plain Bars in tension |

| Design Bond Stress (N/mm2) | 1.28 | 1.44 | 1.6 | 1.76 | 1.92 | 2.08 | 2.24 | For deformed bars in tension |

Factors affecting Development Length:

Concrete’s compressive strength:

The development length needed for bars is inversely proportional to the concrete’s compressive strength, so if the concrete’s compressive strength were higher, this length needed for bars would be lower.

Concrete density:

The development time must be increased if lightweight concrete is being used.

Rebar clear cover:

If we extend the clear cover, this length will shorten.

Rebar center to center spacing:

If the bar spacing is increased, there will be more concrete available for the rebar to withstand horizontal splitting.

In beams, the bars are placed close together, one or two bar diameters apart, while the distance between the bars is greater for slab footing.

Rebar coating:

Epoxy-coated rebars are sometimes used in projects where the structure is exposed to corrosion-causing environmental conditions.

The bond strength among both concrete and rebar is reduced in such circumstances, requiring longer development times.

Advantages of Development length:

- For reinforcement steel and concrete to function together without slipping, a strong enough bond must be provided.

- To maintain the structure’s integrity and allow it to carry the loads, assist in completing the stress transfer process.

- The perfect bond between them ensures that the plane section of a structural beam stays plane even after being bent.

- This design involves the reduction of reinforcement steel, this length becomes absolutely crucial.

- The development and lap lengths, as well as the tension reinforcement for continuous beams and cantilever supports, must be checked for structural stability.

Disadvantages of Development length:

- If we provide less development time than is necessary, the structures will be more vulnerable to failure from joint slipping.

- In such circumstances, the failure will occur at joints and laps before the reinforcement bars eventually break, rather than the bars breaking first.

Also read: Limit State Method and Working Stress Method | Long Column & Short Column

Conclusion:

In reinforced concrete structures, bond strength allows the composite action of concrete and steel.

By allowing enough time for development length, the necessary bond strength is attained.

Failures frequently occur as a result of inadequate development lengths, especially in cantilever supports, lap splices, and beam-column joints.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment