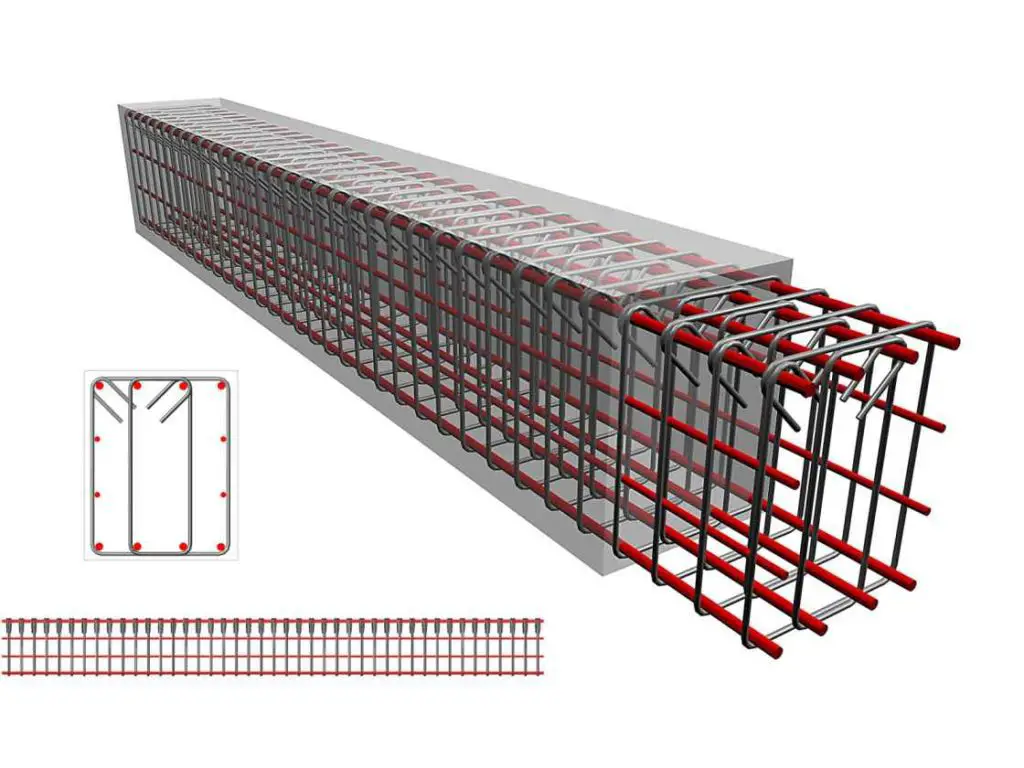

Stirrups are made of rectangular metal components wrapped around the top and bottom strips of beams or columns (rectangular or round in shape).

They are usually perpendicular to the longitudinal direction of the RFT, but they can also be tilted.

The stirrup is utilized to effectively manage shear capacity.

The spacing along the beam is critical, and the expert should specify it if feasible.

In this article you’ll learn:

- Purpose of stirrups.

- Types of stirrups.

- Merits and Demerits of stirrups.

- Lots more.

So, if you’re ready to go with it, this article is for you.

Let’s dive right in.

What are Stirrups?

The stirrups are usually located perpendicular to the longitudinal axis of the RFT, but they can also be tilted.

The major reinforcing bars of a reinforced concrete structure is protected by a stirrup, which is a complete loop of reinforcing steel.

Based on the manufacturer and shape of the portions, it can take on a number of shapes.

Purpose of Stirrups:

- Stirrups are necessary to prevent buckling of columns and beams as well as to aid in lateral resistance.

- This is designed to mitigate shear failure, which is generally diagonal in the case of beam fractures.

- They are utilized to effectively manage shear capacity.

- Stirrup spacing along the beam is crucial, but it should typically be indicated by the expert.

- It helps to keep everything moving in the same way.

- Stirrup assists to keep stability while also providing strength to the structure at vital spots where it is likely to be vulnerable over time.

- This is done to avoid shear failure, however in the situation of beam fractures is usually diagonal.

Spacing between Stirrups in Beam and Column:

Spacing between Stirrups in Beam:

The maximum spacing in a beam should not exceed 300mm or 12′′, and the minimum should not be less than 100mm or 4′′, according to standard regulations and guidelines.

The usual stirrup spacing is 6′′ to 7′′ (150–180mm) inside the center and 4′′ to 5′′ (100–125mm) just at the column’s end support.

Spacing between Stirrups in the Column:

The maximum spacing in a column should not exceed 300mm or 12′′, and the minimum should not be less than 100mm or 4′′, according to standard regulations and guidelines. Standard stirrup spacing is 6′′ to 7′′ (150–180mm) in the middle and 4′′ to 5′′ (100–125mm) at the end support of the column.

Spacing of Stirrups near the Support End:

Stirrup spacing towards the support end is reduced to a minimum due to the supports’ maximum shear forces. The support end of the rectangular beam and column should have a minimum separation of 6′′ to 7′′ (150–180mm).

Types of Stirrups:

Stirrups based on the Nature of Construction:

Single-Legged:

Single-legged stirrups are uncommon, but they might be beneficial when just two poles need to be bound.

They are approximate a flattened U-shape instead of a full loop.

Double-Legged:

Some of the most typical stirrup configurations in the sector are double-legged or two-legged stirrups. To make this stirrup, you’ll need at least four rods.

Four-Legged:

The four-legged stirrup should be the next phase, consisting of two overlapping stirrup that do not encompass all of the shafts.

When there are 8 rods in two rows of 4, the two overlapping stirrup will each encircle six rods, for both covering the four in the center.

Six-Legged:

Instead of an eight-rod configuration, a six-legged stirrup can be used to support it.

In this arrangement, a single stirrup encircles all eight rods, and additional legs give additional support. The extra legs are usually stretched between two adjacent rods.

Stirrups based on the Shape:

- Rectangular Stirrup.

- Square Stirrup.

- Circular Stirrup.

- Triangular Stirrup.

- Spiral Stirrup.

Stirrups used in Column Construction:

1. Helical Reinforcement:

The helical reinforcement distinguishes from the lateral ties in that the lateral ties have spacing between individual bonds, whereas the helical reinforcement has not.

Pitch, not spacing, is the defined value in helical reinforcement. In terms of lateral connections, the helical reinforcement gives the built-up column more elasticity and mobility.

They have the ability to successfully facilitate longitudinal reinforcement. The resistance capability of the column structure against buckling increases with the application of helical reinforcement.

2. Lateral Ties:

Lateral ties are used for transverse reinforcement in addition to creating a separate loop with a specified spacing between each link.

Based on the column cross-section and the number of vertical or longitudinal reinforcing bars used, lateral stirrups are classified as two-legged, four-legged, or six-legged.

Advantages of Stirrups:

- Stirrups provide the beam shear strength.

- It confines the beam and boosts its overall strength.

- It inhibits the movement of major bars during concreting.

- They enhance ductility.

- It resists lateral shear.

- It gives stability to the r/f.

- They inhibit members and individual bars from bucking.

Disadvantages of Stirrups:

- Some designs have an unusual appearance.

- High-quality and large items are more expensive than non-safety stirrups and other designs.

- Maintaining proper leg/foot position might be more challenging.

- Some varieties might not be accepted (or appreciated) in the show ring.

Application of Stirrups:

- Stirrups are used in places where the effect of torsion is negligible, primarily to resist shear stresses in concrete beams.

- They are used in the tension zone of concrete beams to avoid shear fractures.

- Since concrete beams are built to endure severe torsion, a stirrup should always be used.

Also read: Types of Columns | Micropiles | Long Column & Short Column

Conclusion:

If adequate requirements for stirrups are not provided, construction spacing may fail, so the designer should describe the spacing together with the structure.

With so many varieties and pricing ranges to choose from, safety stirrups are an inexpensive method for any rider to be safe without spending a lot of money.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment