The post-tension slab is a combination of traditional slab reinforcement and additional high-strength steel tendons that are subject to stress after the setting of concrete.

Generally pre-cast elements where the strand or bar is stressed before the concrete being poured over it (no ducts used).

Here we will learn about post tension slab, its merits & demerits and why we use post tension slab!

Introduction to Post Tension Slab :

A post-tension slab generally refers to a section of cured concrete, which has tensile forces introduced into the slab after the concrete has been set.

These internal forces are provided by tensioning the high-strength steel that occurs before or after the concrete is positioned.

When steel is stressed before applying the concrete, this course is known as pre-tensioning.

When Post tension slab is required:

- A concrete slab is pressured by a post-tensioning methodology when it signifies that the steel is being pressured and the concrete is being compressed.

- A concrete floor slab is subjected to forces, it flexes and bends.

- Including the post-tensioned reinforcements, instead of rebars reinforces the stress field with the advantages of compressing the solid slab.

Components of post-tension slabs:

1. Nozzles:

Thin sheet metal pipes with claw coupling or welded overlapped seams of 5 and 6 meters length are offered.

The nozzles are attached by an outer screw coupling and wrapped with the PE tape.

In recent days, plastic tubes are also available in the market, they are watertight, frictionless and fatigue resistant.

2. Tendons:

The fundamental element of a post-tensioning system known as the tendon.

Many steel objects are constructed of post-tensioning tendons, which are coated with a protective coating located inside the duct or sheathing.

Prestressed metal is manufactured according to the necessities of ASTM A-416 and the everyday strands are 0.50 and 0.60 inches in diameter.

A characteristic steel strand used for post-tensioning can be around 243,000 psi.

In distinction, a particular piece of rebar will yield approximately 60,000 psi.

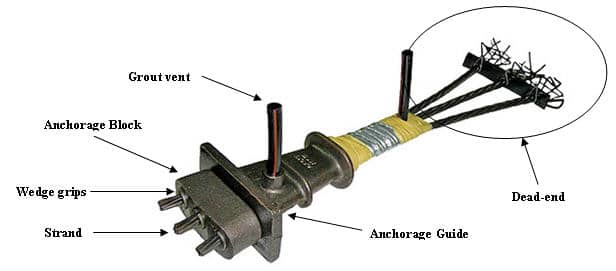

3. Anchoring to post-tension slab:

Anchors are used to anchor the tendons with the concrete.

The main function of anchoring is to transfer the stressing force into the concrete after the tensioning process is completed.

Also read: Flat Slab & Waffle Slab

Advantages of post tension slab:

1. Vastu Benefits:

Post tension slabs have is an environment-friendly base for flooring design with thin slabs and column fewer spaces in larger slabs.

This provides an architect the freedom to work independently with their designs.

2. Commercial Location:

Subsequent stress results in a slab of thin concrete due to the valuable financial savings available from flooring top to extra flooring.

This might present an additional rentable house inside a similar general building height.

3. Reduces dead load:

Since the thickness in the post-tension slabs is reduced, the amount of concrete and reinforcement is also reduced by 20% –30% compared to the conventional concrete slab.

4. Structural Durability:

Post-stress slab reduces the improved durability and decreased maintenance prices.

Their deflection can be managed immediately after stressing different amounts to balance any part of the applied load.

5. Popularity:

The demand for stressed slabs has increased due to its countless benefits for builders, civil engineers, architects, contractors, and other users.

Also read: Concrete slab & Sunken Slab

Disadvantages of Post tension slab:

- Pre-tensioned members are fabricated off-site.

- Delay in delivery or production will cause a delay in the schedule, but the installation is easier and requires an enormous time in the crane.

- A post-tensioned member is installed on-site; once the structure is concreted the stressing is no more critical in the schedule.

- Post-tensioned members are subject to friction loss.

Uses of Post Tension Slab:

- Post-tension slabs are extensively used in bridges, elevated slabs, residential foundations, walls, and columns.

- It is used when spans are large and normal RCC slabs become unformed.

Also read: Types of Slabs & One Way Slab and Two Way Slab

Conclusion:

Post tension slab is a slab where the reinforcement goes through ducts that is made of steel wires (not bars).

The wires have to be made taut by pulling them after the concrete has hardened and before the scaffolding is taken away.

This means that the slab bends upwards, so all the concrete works in compression through the slab, it’s usually called post-stressed concrete, once the mix has hardened, you release the wires.

The effect is the same as the slab is bent upwards by the tension and there are no sections of the slab where the concrete is “pulled”.

Your opinion of what is best. I have 2 quotations from concrete contractors to install a 30′ x 60′ slab, outside (a pickle ball court). One for post tension and then other for reinforced concrete. Do you have an opinion of which would be better, both are quoted +/- 10%. thanks, Tony Bardsley