The Rock Quality Designation (RQD) is critical in geology and civil engineering.

RQD is a vital aspect that geologists & engineers depend on RQD while planning projects such as constructing foundations or tunneling.

In this article, we shall study the details of RQD or Rock Quality Designation in geology, its merits, demerits & uses.

What is Rock Quality Designation(RQD) in geotechnical engineering?

RQD is a metric for calculating the quality of rock core samples gathered during drilling operations.

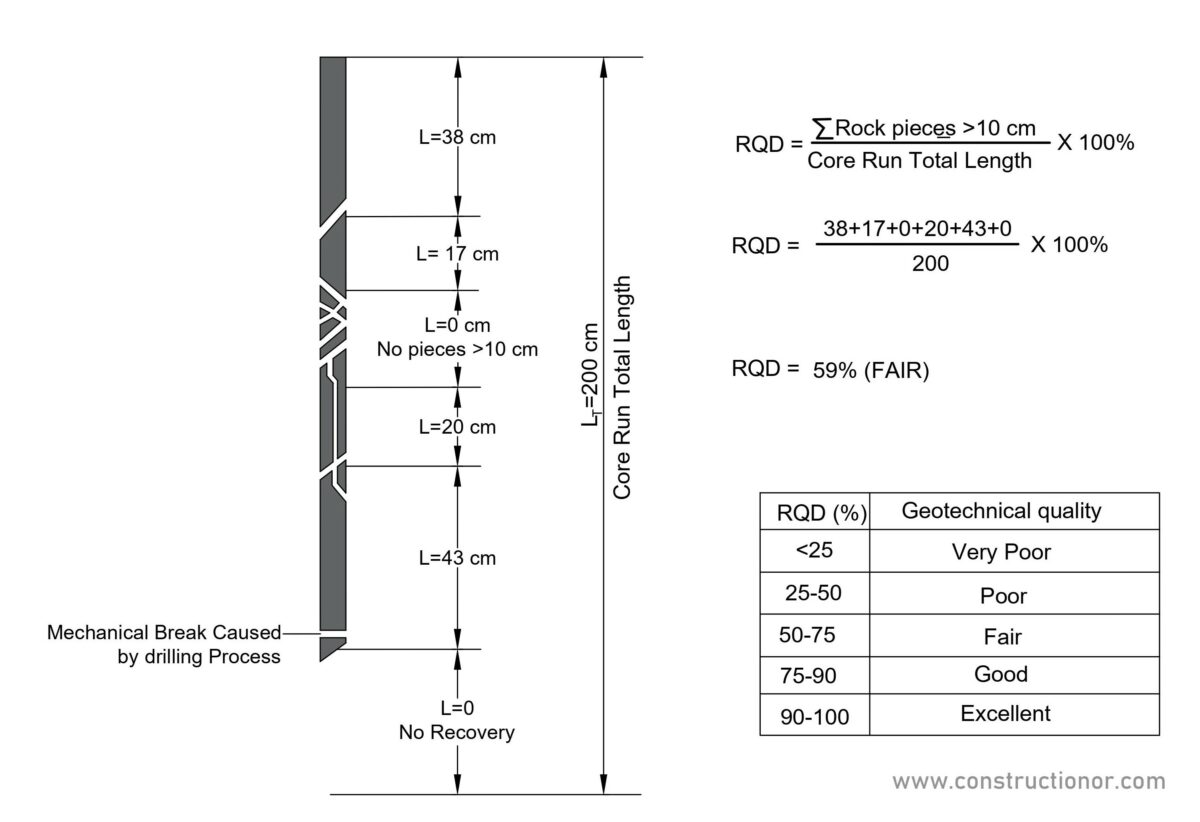

Rock Quality Designation Definition: Rock Quality Designation (RQD) is an essential measurement of joints or fissures in rock masses calculated as a percentage of drill cores 10 cm or more in length; the high-quality rocks have an RQD value greater than 75%, whereas the low-quality stones have an RQD value of less than 50%.

Rocks more significant than 100mm shall not be considered while calculating RQD.

It is used in geology and civil engineering to evaluate the quality and capacity of rock formations.

RQD is capable of providing crucial knowledge into the strength and integrity of rock masses critical to various construction and mining projects.

History of RQD:

Don Yu Deere developed RQD in 1964 as a way to measure joints or cracks in rock cores.

Then, it quickly became an ordinary procedure in geotechnical engineering.

Determination of Rock Quality Designation (RQD):

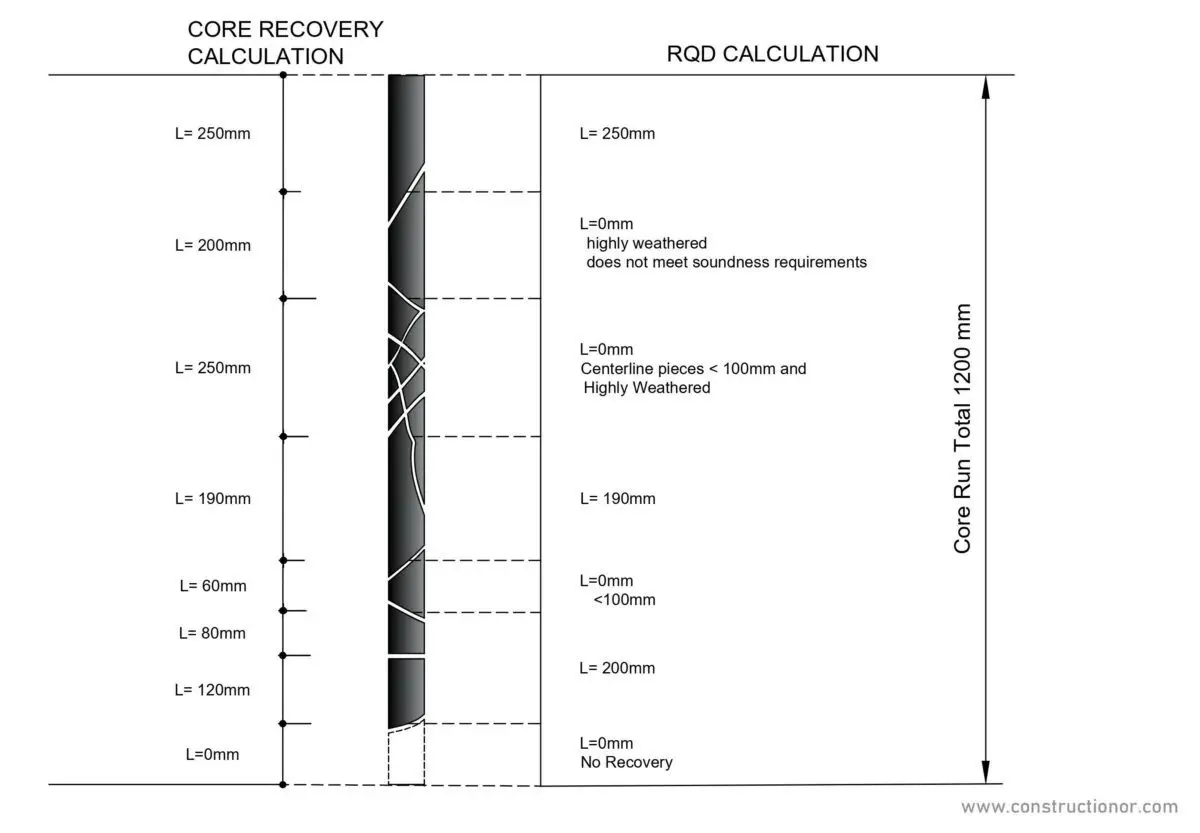

For the calculation of roux core recovery and RQD, see the following process:

Rock core recovery calculation:

Core recovery is calculated by the following formula:

Core recovery (CR) = (total length of recovered rock / total core run length) x100

There, the total length of the rock = 250 + 200 + 250 + 190 + 60 + 80 + 120 = 1150 mm

Total core run length = 1200mm

Therefore, core recovery (CR) = (1150/1200) x100 = 96%

Rock quality designation RQD = (SUM {sound piece length> 100 mm} / total core run length) x 100

SUM {length of sound pieces> 100 mm} = 250 + 190 + 200 = 640 mm

Therefore, RQD = (640/1200) x100 = 53% which are rocks of fair quality, i.e. the rocks are of medium scale.

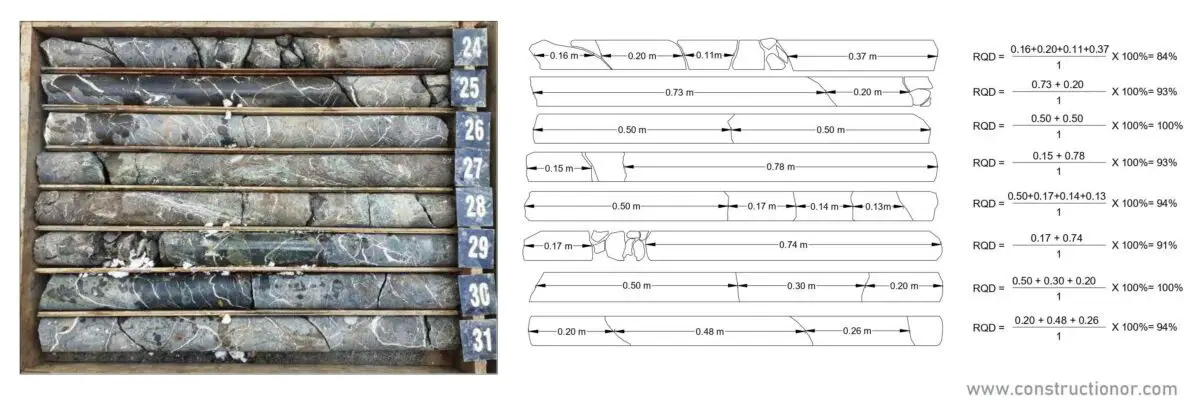

Rock Core Samples for RQD Calculations:

The following table shows the values of RQD of different quality of rocks.

| Rock Quality | RQD (%) |

| Very poor (completely weathering rocks) | <25% |

| Poor (cracked rocks) | 25 to 50% |

| Fair (moderately pitted rocks) | 51 to 75% |

| Good (hard rock) | 76 to 90% |

| Very good (fresh rocks) | 91 to 100% |

Necessary Measures:

Rock quality designation is used with all core sizes other than BQ and BX cores are perfect with NQ core sizes.

The core brakes initiated by the drilling process must be fitted collectively and calculated as a single piece of sound core.

Drilling brakes are typically eliminated by rough fresh surfaces & for the laminated rocks, it would be difficult to classify core breakage due to drilling.

In this case, RQD should be conservatively estimated:

For classification of shear strength, do not calculate the size of the near-horizontal fissure.

Whereas, for estimates of rock blasting requirements, it is customary to estimate the length of the horizontal gap approximately.

Factors Affecting RQD Values:

Several reasons that can modify RQD values, including:

1. Climate:

The weathering undergone by means of rocks has a tremendous influence on their RQD values.

Rocks that have undergone weathering tend to exhibit lower RQD values in their overall integrity.

2. Fracturing:

Faults and fractures may reduce RQD values as they interfere with rock mass continuity.

3. Drilling method:

The drilling method utilized may affect RQD values.

Appropriate drilling processes must be used to limit core fracture and allow reliable RQD measurements.

Understanding RQD Values:

Analysis of RQD values requires knowledge of their consequences for specific purposes; Higher RQD values suggest a more cohesive and proficient rock mass.

However, “high” RQD might vary based on industry and project requirements.

Advantages of Rock Quality Designation (RQD):

- This test provides an evaluation of the soundness of the rocks and the damage because of weathering.

- It is helpful to determine weak rock zones which are crucial in the construction of heavy structures.

- RQD has many functions in mining, engineering geology, and geotechnical engineering.

- Tunneling situations are also determined.

Disadvantages of Rock Quality Designation (RQD):

- Rock quality designations have variable values relying on the direction of the track.

- It doesn’t provide data on core pieces that are lower than 10 cm.

- This provides incorrect values in where the joints comprise thin clay filler or weathering materials.

Applications of RQD:

1. Civil Engineering:

Engineers utilize RQD values to analyze whether the rock mass suits various projects like tunnels, dams, and foundations.

A higher RQD indicates more stability; therefore, the probabilities of structural failure are lowered.

2. Mining and quarrying:

RQD provides resource valuation and planning assistance to the mining and quarrying industries, assisting mining professionals in evaluating ore characteristics and mining capability.

High Rock Quality Designation (RQD) values serve as an indicator of ore-intact areas with easier mining operations.

It makes RQD an invaluable tool in investigations.

3. Geological Research:

Geologists use RQD analysis to study rock formations’ history.

To understand the history of a location, scientists can examine its characteristics, like the impact of forces, climate processes, and geological events.

Also read: Standard Cement Consistency | Modulus of Rupture | Fineness Modulus of Cement | CBR Test

Conclusion:

For geologists and civil engineers, RQD (Rock Quality Designation) is essential information signifying the stability and quality of rock formations.

This information is beneficial in many rock-related decision-making situations.

Calculating and evaluating RQD values are extremely important for professionals who deal with rocks, whether they are assessing rock conditions or scenarios.

Also read: Chemical Oxygen Demand (COD) | BOD [Biochemical oxygen demand] | Slump Test

Frequently Asked Questions:

RQD is the percentage of continuous drill core pieces longer than 10cm during a core run,

Rock mass classification systems are used for various engineering design and stability analysis.

RQD = (SUM {sound piece length> 100 mm} / total core run length) x 100

RQD plays a crucial function in civil engineering by helping engineers make effective judgments about construction methods and safety precautions.

Yes, RQD value can be subjected to wide variation depending on geological conditions, weather, presence or absence of fractures, among others.

The primary problems regarding RQD in rock masses are low recovery of core, stop logging along the rock length, and occurrence of joints and fractures.

Engineers can improve the Rock quality designation of a rock mass through grouting and rock bolting to promote stability, hence improving RQD.

Related Posts

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment

Standard Cement Consistency