A cement standard consistency is determined by how far the Vicat plunger can penetrate from the Vicat mould base measured in millimetres (mm).

In this article you’ll learn:

So, if you’re ready to go with standard cement consistency, this article is for you.

Let’s dive right in.

What is Standard Cement Consistency?

The normal consistency of cement paste depends on the amount of water added to the 300gm weight of cement.

It will enable a Vicat plunger with dimensions of 50 mm in length and 10 mm in diameter to pierce cement paste 33–35 mm below the mould’s top.

Purpose of Standard Cement Consistency:

- Since the quantity of water added to cement affects the setting time, it is crucial to understand the typical consistency of cement.

- Less water added than standard consistency would not complete the chemical reaction and will increase the strength of the concrete, and more water would raise the water-cement ratio will decrease the strength of the concrete.

Determination Apparatus for Standard Cement Consistency:

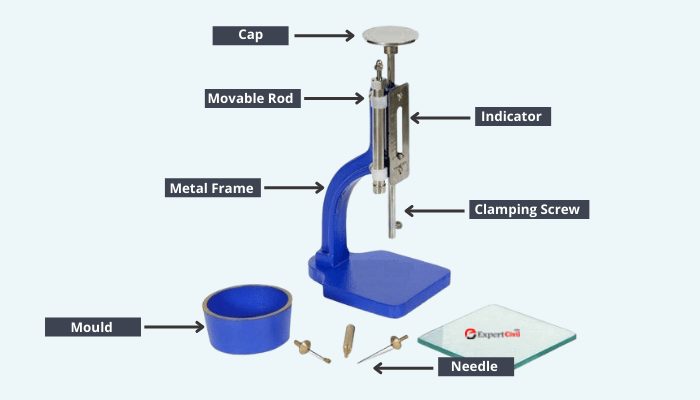

1. Vicat apparatus:

The Vicat apparatus is made up of a frame and a moving rod with one end having a cap and interchangeable attachments listed below.

Measuring device for the first setting time.

Calculating tool for the final setting’s timing Plunger used to assess the consistency of the requirements.

2. Needles:

Initial Needle Setting Time: The needle has a 1 mm2 cross-section.

Final Needle Setting Time: The needle has a 1mm2 cross-section and is rounded.

The needle is attached with metal.

The cutting edge of the hollowed-out metal attachment is past the needle’s tip.

Plunge for Consistency in Standards:

It is constructed of polished brass that has a projection at the top end that may be placed into the moving rod.

Its diameter is 10 0.05mm for cement standard consistency.

3. Movable Rod:

A moving indication on a flexible rod covers a graduated scale that is attached to the frame (certain models have an additional attachment of dashpot, which facilitates lowering of movable rod slowly).

4. Graduated Scale:

The graduated scale’s smallest division with a length of 40mm is 1mm.

5. Vicat Mold:

A single mould Vicat’s mould is shaped like a cone frustum that has internal measurements of 40 +/- 0.5 mm in height, 70 +/- 0.5 mm at the bottom, and 60 +/- 0.5 mm at the top.

The split type Vicat mould can be used as an alternative to the single mould.

This mould is a split ring with an internal diameter of 80+/-0.1mm and a height of 40+/-0.5mm.

A non-porous base plate is readily available.

The split mould comes with a suitable clamping ring.

Procedure for Cement Standard Consistency:

- Maintain a level surface for the Vicat apparatus (when using the Vicat apparatus with a dashpot, keep the bearing movable rod to its highest position and pin it.)

- Take out the top screw on the dashpot. Half-fill the dashpot with any suitable oil that has the right viscosity, then tighten the lid.

- Push the valve down many times.

- Join the flexible rod to the plunger that is used to gauge standard cement consistency.

- Add some water to a weighted beaker and 400 g of cement to a pan.

- Create a paste using watered-down cement.

- Start the stopwatch as you add water to the cement.

- Put the Vicat mould filled with cement paste on a non-porous plate.

- After the mould has been completely filled, shake it slightly to let out any trapped air.

- Sand the paste’s surface until it is flush with the top of the moulder.

- After making the cement paste, the test block is made.

- Place the test block resting on the non-porous plate underneath the moving rod containing the needle.

- When utilising a Vicat apparatus with a dashpot, place the mould filled with cement paste and the non-absorbent plate on the Vicat apparatus’ base plate.

- In order to make contact with the top cap of the movable bearing rod, raise the plunger of the dashpot.

- Remove the pin holding the movable bearing rod to the surface of the cement paste, then quickly release it by pressing the plunger into the paste.

- Create trial test specimens for standard cement consistency with varying water content percentages until the plunger is 5 to 7 mm from the base of the Vicat mould.

Observations and Calculations:

Weight of cement taken (g) = _________

Initial percentage of water added to cement = __________

Quantity of water added to cement =_______

Table:

| SL. NO. | QUANTITY OF WATER ADDED (ml) | DEPTH OF PENETRATION (mm) |

Standard Cement Consistency = (Quantity of water for 5-7 mm penetration/Weight of cement) X 100.

Important Points:

- The measurement period shouldn’t be less than three minutes or more than five minutes.

- Measuring time is the amount of time that passes between pouring water to dry cement and starting to fill the mould.

- The test should be performed at 27°C +/- 2°C at room temperature.

- The working table shouldn’t shake at all.

- Every iteration should involve cleaning the plunger.

Also read: Fineness Modulus of Cement | Modulus of Rupture | Slump Test

Results:

Water content as a percentage for consistency cement standard is %.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment