The shear key is used in many different types of structures, such as bridges, retaining walls, etc to provide resistance against lateral loads like earthquake loading and sliding forces.

In this article you’ll learn:

- Purpose of the shear key.

- Classification of the shear key.

- Merits of the shear key.

- Lots more.

So, if you’re ready to go with shear key, this article is for you.

Let’s get in right now.

What is Shear Key?

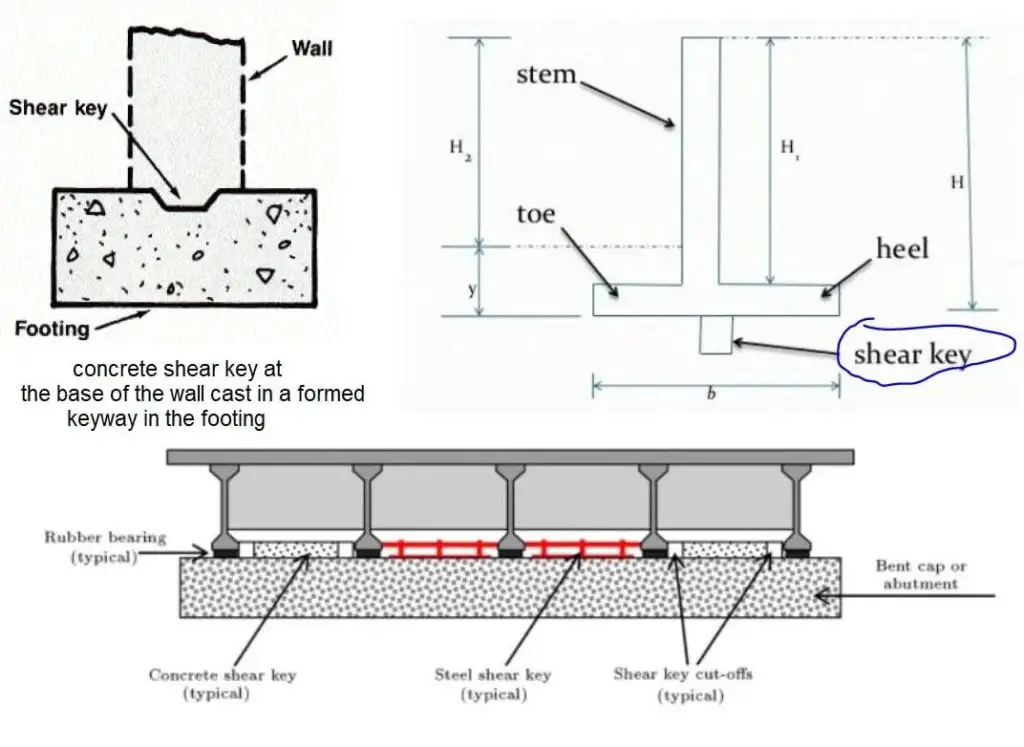

The shear key is a structural component primarily used to stabilize the structure against lateral loads.

Shear is applied depending upon the type of construction project and the type of loading.

Shear keys can be made of steel, as in the case of steel column base plates, or of concrete, as in precast structures, basements of residential buildings, and occasionally steel reinforcement is used to serve as a shear key, for example between a basement wall and a footing.

Purpose of Shear Key:

- Maintaining the structure’s integrity is the main goal of the shear key.

- We generally do not transmit the bending moment through the shear key, even though we permit the transfer of shear forces.

- To put it another way, the shear key at the joint transfers the shear force caused by the applied loads or caused by lateral loads between the two parts of the structure.

- Shear keys offer resistance to lateral forces like wind, earthquakes, and pressures from the earth and water.

Classification of Shear Keys in various Structures:

1. Bridge Structure:

To give the superstructure of small to medium-sized bridge structures lateral transverse support under lateral loads, shear keys are inserted into the abutments.

Shear keys in bridge construction are crucial for mitigating seismic loads.

Shear keys should act as a compromise structural component during a strong earthquake to stop the transmission of significant seismic forces to the abutment piles.

The interior and exterior shear keys are the two different types of shear keys used in bridge construction. The convenience of repair and maintenance is a drawback of the former.

2. Retaining Walls:

At the foundation of retaining walls, shear keys are available to increase the walls’ resistance to sliding.

Positioning the shear key underneath the the retaining wall’s stem is practical because it makes it simpler to implement reinforcement that can be extended from the stem straight into the stem.

ACI 318-17 states that in order to establish the key’s strength in shear instead of flexural, the shear key must be dimensioned so that its width is at least twice as large as its depth.

The shear key is built 0.91 meters from the footing’s toe, and it measures 0.508 meters in width and 0.381 meters in depth.

3. Wall Footing Basement:

At the intersection of the footing and basement wall, shear keys are available. It is cast as an integral part of the wall that extends into the footing’s keyway or groove.

When working on residential projects, an upturned shear key that was cast as part of the footing is occasionally employed.

The purpose of reinforcement bars is to resist bending, but bars that are stronger than those required for bending can also withstand shear, which is why they can be used in place of shear keys.

4. Steel Column Base and Footing Joint:

To resist shear force at the base of the column, a special shear key like a block of I-stub, T-section, or steel pad welded to the bottom of the base plate, is used.

5. Precast concrete Component Connections:

Shear keys are used in precast constructions to join two distinct precast components and raise the joint surfaces’ shear resistance.

6. Masonry Wall:

To withstand out-of-plane forces between adjacent blocks during earthquakes, masonry blocks are manufactured in seismic areas with shear keys.

7. Shear Keys in Slabs:

Shear keys are offered in accordance with the loads applied and the span of the slab. If there’s not a larger span, we could prevent the key in the slab.

Further thinner slabs make it very challenging to form a shear key. As a result, for slabs with a thickness of 150 mm or less, a key is typically not provided.

Additionally, pockets formed in the shape of shear keys were positioned in the slab to create shear keys.

They could be 600 millimeters apart. The engineer chose this spacing based on the slab span and imposed loads.

8. Shear Keys in Beams:

Due to the size of the resource constraints, the length of time required to complete one pour, etc., it is not possible to build a floor slab in a single pour.

And thus, it takes two or more pours to finish concrete slabs. The slab and the beams will have a construction joint. Each beam and slab must have a shear key.

The beam shear keys are positioned similarly to how slabs are. In addition, we typically insert shear dowels into the joints where beams are constructed.

These numbers may, however, be changed in accordance with any additional conditions.

9. Shear Keys in Raft Foundations/Mat Foundations:

Shear keys are usually present in the mat foundations due to the volume that requires to be poured and to lessen the thermal properties.

The keys that are provided to carry the shear forces in the foundations have standard measurements.

Shear keys are typically not designed because they are very stiff and can support the applied loads.

The shear key type could be inserted into the raft foundations. Water stops are offered based on the construction’s nature.

Water stops could be put at the bottom or in the centre of the foundation. The based water bars are typically positioned at joints where there is motion.

Benefits of Shear Key:

- These assist in reducing the problem with sliding stability.

- To offer protection against lateral loads like seismic loads and sliding forces.

- In order to strengthen the bond between concrete surfaces.

- Shear keys are not only applicable to cast-in-place concrete.

- The bonding of new and old concrete can be greatly improved by shear keys.

Also read: Shear Wall | Modes of shear failure | Stirrups

Conclusion:

Shear keys significantly minimize sliding of the wall but increase design moment and rotation in the stem of the wall.

A footing’s shear key must be able to withstand greater forces and deformations.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment