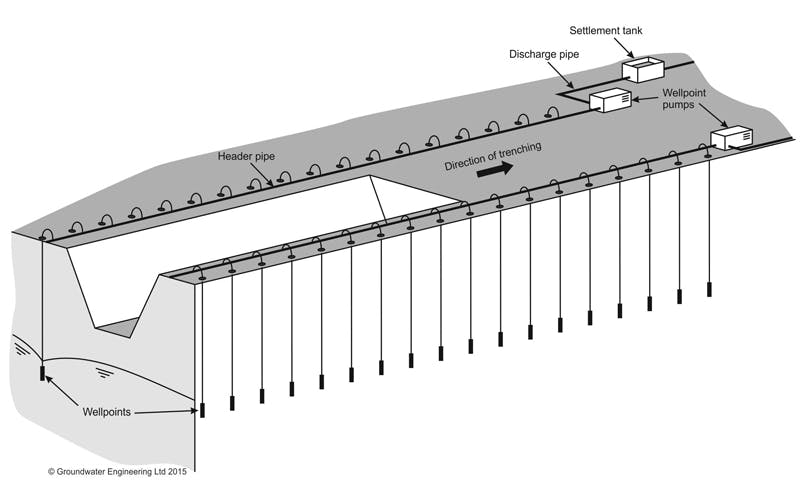

A wellpoint system is made up of numerous sparsely spaced water abstraction points with small diameters that are connected to the vacuum side of the right pump by a manifold.

The pumping system that is most frequently used for shallow excavations, particularly trenching excavations, is the wellpoint method.

In this article you’ll learn:

- Purpose of the wellpoint system.

- Types of wellpoint system.

- Merits and Demerits of the wellpoint system.

- Lots more.

So, if you’re ready to go with the wellpoint system, this article is for you.

Let’s dive right in.

What is Wellpoint System?

A wellpoint system is used for dewatering because it can be used for a variety of excavations and groundwater situations.

Dewatering of the water plays a significant part in determining the project’s overall completion time in many projects.

Several pump sets are accessible at a specific distance depending on the needs of the site.

For such a wellpoint dewatering system to work more effectively or efficiently, the ground hierarchies must usually be permeable in order for the wellpoint to draw groundwater.

Purpose of Wellpoint System:

- Wellpoint is usually placed close to or around an excavation, this method can draw water up to a height of roughly 6 meters using a vacuum.

- Wellpoint can be installed gradually as the excavation progresses in order to operate at deeper depths.

- They are used to lower groundwater levels for steady work practices. A header pipe connects each of the small-diameter wells in the system to the wellpoint pump.

- The pump makes a suction in the header pipe in order to lift water out of the ground.

Types of the Wellpoint System:

1. Single Level Wellpoint:

A wellpoint is made up of a pipe that is 50 mm in diameter and 1 m long. This has perforations that are protected by a screen to keep clogs out.

On the lower end, there is a jetting nozzle available. Also serving as a driving point is this nozzle.

Water can only flow downward while the wellpoint is being installed thanks to a ball valve that is provided near the lower end.

A riser pipe with much the same diameter as the wellpoint is attached to the bottom end of the wellpoint.

The header pipe, a horizontal pipe at ground level, is where the riser pipes are connected.

Header pipe is attached to a pumping device and wellpoint is kept separate by between 0.6 and 1.5.

Water is jetted through riser pipes in a downward direction to insert the wellpoint to the necessary depth.

Once it has been installed, pumping is kept going until all excavation work has been done. While excavation is less than 4.5 meters deep, a single-stage well point system is employed.

In soils with granules, they work well. The water table is lowered by 4.5 meters using the single-stage well point stage method.

This approach is appropriate for soils with permeability coefficients between 10-2 and 10-4 cm/sec.

2. Multilevel Wellpoint:

If excavation is greater than 4.5 meters and a slope failure is possible, these systems are used. The installation of the wellpoint occurs in stages in this system.

Wellpoint is set up in the first stage to a depth of roughly 4.5 and used until the water table is lowered by about 4.5 m.

After that, the area is excavated to a depth of 4.5 meters. Following this, the already-excavated area has second stages of wellpoint installed.

Another 4.5 m of water table lowering has occurred. The excavation is conducted in this manner until it reaches a depth of about 15 meters.

Excavations deeper than 15 m cannot be made using the wellpoint system.

Installation Process of the Wellpoint System:

- There are three different kinds of wells: driven, dug driven, and bored/drilled. Driven well types employ well points.

- The depth of the water table will determine how deep the wellpoint needs to be.

- Location is crucial when using wellpoint. For easier installation of the wellpoint system, moist soil strata may be preferred.

- While installing your wellpoint precisely, the entire point must be below the water table; alternatively, the pump will only suction air.

- Please be aware that as the pump runs, the water table will ultimately lower, necessitating a point that is lower than the pump’s capacity is able to link the water table down.

- Ensure the wellpoint is submerged the entire length and, if possible, at least 2 feet beyond that to compensate for changes in the water table.

Advantages of Wellpoint System:

- Wellpoint can be quickly installed in the majority of ground conditions.

- They require little upkeep.

- It is also possible to use steel self-jetting wellpoint, which are beneficial in environments with little room for expansion and reusable.

- To rapid depressurization of confined layers encountered during construction, a wellpoint can be installed inside tunnels and cross-passages.

- In locations with difficult soil properties, such as open gravel or overburden firm clays, wellpoint can be embedded using a small rotary drilling rig and either temporary casing or conventional and hollow-stem augers.

Disadvantages of Wellpoint System:

- Only water tables below 5 to 6 meters are recommended for use with the Wellpoint dewatering system.

- It is recommended to use the caisson foundation method for deeper excavations.

- Until the required water level is achieved, the wellpoint must keep running.

- Using a machine-drilled hole is necessary for operating well point systems in soil that contains large boulders, clay, and gravel, which will raise the cost of installation.

Applications of Wellpoint System:

- Building an underground water tank.

- The process of building foundation excavation.

- Lengthy sewer lines laying.

- Digging a tunnel work.

- Building of subways.

Also read: Submersible Pump | Reciprocating Pump | Centrifugal Pump

Conclusion:

The technique of well-pointing systems will be covered in this article.

The vertical wells are connected to the vacuum pump via a common header pipe and closely spaced 1 meter (3′) to 3 meters (10′) apart when this technique is used.

High-pressure water jetting or the newly developed White water rafting situations that encourage systems are used to install wellpoint because they do not require high-pressure pumps or on-site water storage.

This leads to less crowded, cleaner sites and safe, quick, simple well point installation.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment