Curb and gutter are usually installed in the perimeter of the road or parking lot, the curb is a small wall that serves to hold the pavement from the sides acts as a barrier between the yard and road.

It is filled with a gutter that is a flat concrete slab that drains water out of the yard, normally curb and gutters are constructed simultaneously at a site.

Difference between curb and gutter:

The Curb (North America) or Kerb (UK) is a row of concrete along the roadway, while gutter is a channel prepared in a surface, especially along the side road.

Curb intended for the drainage of water or gutter can be which guts.

types of curb and gutter:

Mountable Curb and gutter:

The mountable curb has a light dip on one face of the hook, so that it allows vehicles to easily drive over it.

This type of curb is preferred for pedestrians with shopping carts or strollers, and those on bicycles or roller-skates to cross safely on or off the pavements.

Mower Curb and gutter:

Mowers curbs are used in lawns or flowering areas, where they have a very decorative look and provide a strong, reliable, and protective barrier between the walkway and the green zone.

Their exclusive shape makes it possible for lawn cutter to ensure that each blade of grass is trimmed evenly without damaging or damaging machinery.

Barrier Curb and gutter:

It is the most commonly used curb worldwide.

This type of curb is used as a barrier between vehicles and certain locations (e.g. sidewalks, stores, parking spaces, etc.).

Barrier curbs are usually made of asphalt aggregates or cement concrete.

Monolithic Curb and gutter:

The monolithic curve is constructed or connected with the roadway.

The top-level makes it easier to pass without creating other tracks for larger vehicles without damaging the internal structure or foundation of the concrete.

Slanted Curb and gutter:

Slanted curbs have no practical purpose, they enhance the aesthetic nature of the surroundings.

These are purely ornamental and ornamental courses.

Standard curb and gutter dimensions:

(A) Vertical Curb to Be Used in Commercial Zones.

| Back wall of the curb in height | 12 inches |

| Curb top in width | 6 inches |

| Curb face in height | 6 inches |

| Curb face slope in six inches | 1/2 inch |

| Curb face and apron radius | 1 inch |

| Gutter width | 18 inches |

| Gutter thickness | 6 inches |

| (8) Gutter slope to curb face | 1 1/2 inches |

(B) Rolled Curb to Be Used in Residential Zones.

| Back wall of curb in height | 10 inches |

| Curb face height above flowline | 5 inches |

| Curb face slope | 12 inches |

| Gutter width | 18 inches |

| Gutter thickness | 6 inches |

| Gutter slope to curb face | 1 1/2 inches |

Curb and gutter specifications & construction process:

1. Marking and Excavation:

The marking is the first and most important phase of every construction activity; marking powder is used on the way in which the hook and drain are to be built.

Necessary shields are provided to ensure that all the water on it flows efficiently; the marked area is then excavated to a depth of 300 mm with manual or mechanical means.

All loose soil and dirt are firmly filled using a hand manipulation or mechanical compactor, the base of the gravel mixed with cement is laid down and compacted.

The gravel base for both the curb and gutter is placed at once and the width of the gravel base will be the joint width.

2. Formwork:

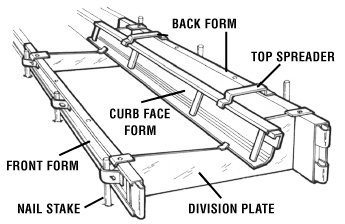

Formwork is made with the use of ply boards or steel moulds, the design of the formwork depends on the type of curb to be manufactured.

The form-work is built and secured with a wooden wager driven into the ground with a hammer behind them.

Fasten the two boards together to hold the spacers in place using nailed metal clamps or 1-by-2 boards on top of the curb form boards about each foot.

Spacers are provided at regular intervals.

Plumb work and formwork levels are checked for proper alignment and correct size.

Coat formwork with cooking oil or similar material to prevent concrete.

3. Replace Concrete:

The concrete of the required design mix is placed in the formwork.

First, the concrete is poured into the drain-field, then the top of the curb formwork is filled with concrete; proper compaction is ensured for a durable hook and drain.

After the concrete is set, remove the front curb board, lubricate the surfaces of the curb and gutters with the help of special concrete finishing tools.

The concrete in the gutter is finished with a finishing device that creates indentations where the spacers were placed as a curb; remove spacers and fill those joints with concrete mortar.

4. Treatment:

When the concrete has been laid and finished, it must be cured to develop strength and durability.

Avoidance of moisture loss, rain damage, traffic and extreme hot or cold temperatures.

Also read: Road Drainage, Canal, Culverts & Surge Tank

Advantages of Curb & Gutter:

- Adds parking area and enhances adjacent properties by the sharper separation between roads and lawns.

- When laying the pavement, the curbs form a closed boundary, and improve compaction during construction helps in maintaining the integrity of the edges under traffic.

- Drainage reduces the amount of space required for a road or the correct route by eliminating drainage and their leveling slopes.

- The light reflective surfaces of the concrete curb crossed the pavement edges and improved visibility for drivers at night thus promotes safety.

- Curbs improve the efficiency of road sweepers by centering debris for easy and mechanical spontaneous.

- Gutters successfully help to drain water that slides down from the other side of the pavement, thus preventing water from entering the pavement area.

Disadvantages of curb & gutter:

- The construction process requires skilled labor.

- It adds extra construction cost.

- In the rainy season, the gutter may choke up leads to extra water on the road.

Also read: Cross Drainage Work, Weep Holes, Weir & Fish Ladder

Conclusion:

The curb and gutter are provided to strengthen the pavement which is being laid as the road surface.

It is poured before being brought, normally about 8 inches thick and forms an extremely strong barrier.

How interesting that you mention what the monolithic curve is and how it’s constructed. I am starting a new contractor business this year. I will find a reputable kerbing service in the area to help with this.