There are different types of pumps to transfers the water or gas, while we had made a detailed classification of pumps with merits & demerits.

A pump is a device that is used to transfer fluids which may be liquids or slurries from one point to another.

These pumps circulate fluid flows through the system over great distances which are unrestricted and uninterrupted.

Different Types of Pumps in Construction:

The pumps can be classified by using different criteria, following are some of the essential criteria used for classifying the pumps:

Classification of pumps Based on the Principles of Operation:

1.Displacement pumps:

The movable parts of the pumps create a vacuum.

This is done mechanically, i.e. the water is withdrawn into the pump by pressure, the mechanical part is displaced and the water is exhaled through the valve.

The backflow of water is prevented by using appropriate types of valves.

The displacement pumps are further classified as follows:

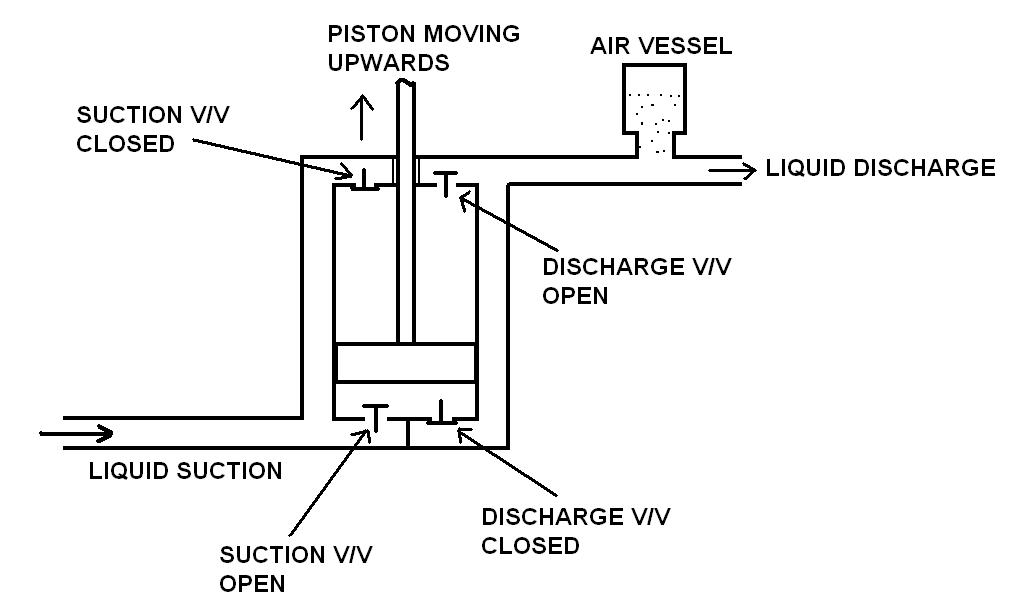

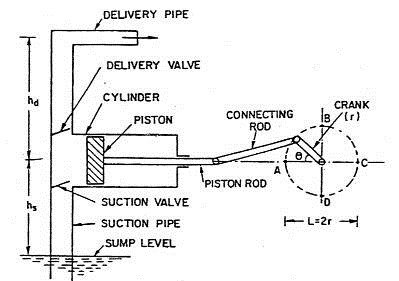

A) Reciprocating pumps:

The reciprocating pump is a positive displacement pump where a particular amount of liquid is collected in an enclosed volume.

It is discharged using pressure for the required application.

Reciprocating pumps are more suitable for low volume flow at high pressures.

These pumps also can be further divided as,

- Simple hand-operated reciprocating pumps.

- Power-operated deep, well reciprocating pumps.

- Single-acting reciprocating pumps.

- Double-acting reciprocating pumps.

Advantages of reciprocating pumps:

- The reciprocating pump gives high pressure at the outlet which has a high suction lift.

- This pump does not require priming.

- They are also used for wind.

Disadvantages of reciprocating pumps:

- High wear and tear therefore requiring very high maintenance.

- The initial cost is very high.

- More substantial and heavier in size.

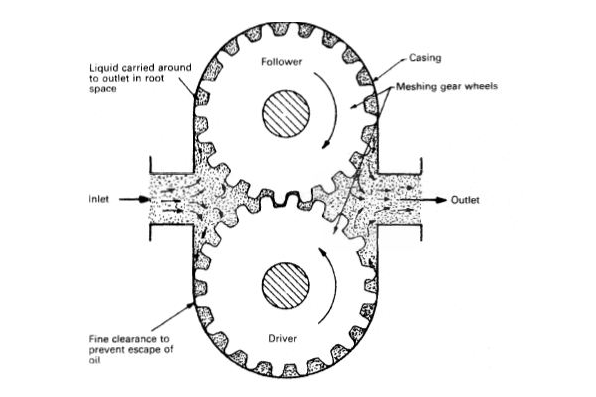

B) Rotary Pumps:

In these pumps, rotating blades fit into the casing, and these blades push water through their displacement.

The water is pushed upward through the discharge pipe.

Rotary pumps are of two types such as

- Gears rotary pump and

- Rotary pump.

Advantages of rotary pumps:

- They are self-primed.

- Their efficiency ranges from low to medium (up to the discharge of 2000 liters/minute).

- They have no valves and easy to manufacture.

- Also, give steady flow.

- They can also be used for personal use in the building for fire protection.

Disadvantages of rotary pumps:

- The required cost of the pump is high.

- Due to the abrasion of cams and gears, the maintenance cost increases.

- They are unable to pump water with suspended material.

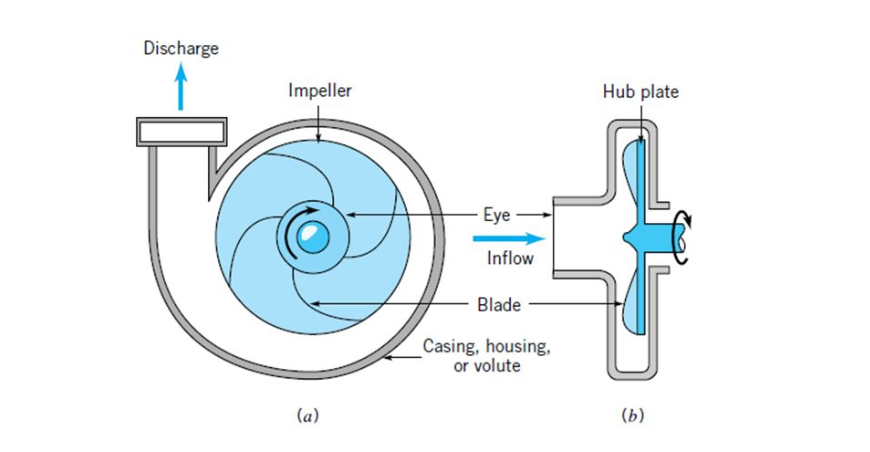

2.Centrifugal pumps:

This centrifugal pump is designed to operate on the principles of centrifugal force.

The water entering the pump is rotated at a very high speed using an impeller.

Due to the centrifugal force, water is sent to the periphery.

Depending on the function, centrifugal pumps are classified as follows:

A) Volute pumps:

In volute pumps, the velocity of water remains the same at all points in the channel allowing the water to be distributed at a higher rate in the pipe.

B) Turbine pump:

In turbine pumps, the velocity of the water decreases before it enters the casing, these pumps converted the velocity head into the pressure head.

These types of pumps are classified on the basis of the number of impellers used, i.e. the centrifugal pump using one impeller is known as a single-stage pump and where more than one impeller is used are known as double or multi-stage pumps.

Advantages of centrifugal pumps:

- As centrifugal pumps are compact, they require less space.

- They can be fixed to a high-speed driving mechanism.

- Due to its rotary motion, no noise is produced.

- The cost of production, therefore the price is low.

- The fixed easy mechanism, operation, and repair are also safe.

Disdvantages of centrifugal pumps:

- Additional priming is required.

- High head may not be able to work.

- Cannot deal with high viscous fluid.

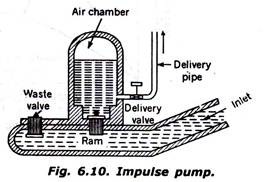

5.Impulse pump:

It is also known as a hydraulic ram and works on the principles of impulse.

By using a hydraulic ram, the water can be lifted to a considerable height.

These types of pumps have an inlet pipe, waste valve, distribution valve, piston, air chamber, and distribution pipe.

When this waste valve is not operating it is kept open, and the delivery valve remains closed.

Advantages of the Impulse pump:

- Impulse pump has very long durability.

- The work is very simple.

- No external power is required to operate the pump, therefore it is very cheap to operate.

Disadvantages of the Impulse pump:

- When it is in operation, it produces noise.

- The dissipation of water is very high, it varies between 6: 1 and 2: 1.

Also read: Concrete Pump & Submersible Pump

Classification of pumps Based on the power used:

The pumps are operated using various electrical engines, which based on the energy used to drive the drivers, we can classify them as follows:

4.Electric motors:

They are used in the area where power supply is available.

Generally for city water supplies, electric motors are used because they operate during the off-peak period.

When the electric motor is to be selected for the pumping station, its cost, simplicity, roughness, power factor starting torque and variation in speed are some of the essential points that are considered.

5.Gasoline or Oil Engine:

The cost of these engines is so high that they are commonly used as reserve arrangements.

These type of pumps that are used in remote areas where electricity is not available.

6.Steam engine:

Steam engine was used in the past when electricity was not available.

Now in most places, they have been replaced by electric motors.

Also read: Types of Pipes, Types of Arches & Types of Valves

Conclusion:

There are many types of pump designs, but they are classified into centrifugal pumps and positive displacement pumps.

For performing the construction activity properly, the correct type of pumps must be specified for each application.

Related Posts

Rock Quality Designation(RQD): Building Strong Foundations

Spread Footing

Masonry Cement

Plain Cement Concrete

Concrete Efflorescence

Concrete Pile

Stepped Footing

Fineness Modulus of Coarse Aggregates

Difference between Condo and Apartment